This page uses Norcolds words to compare the Fridge Defend by ARP versus Norcold Recall and why Norcold leaks result in RV fridge fires that may have been prevented.

On this page the brown fonts are quoted from Norcold letter to us & Norcold NHTSA letter.

The red fonts are quotes from Norcold patent application

13/279,361

menu item

Norcold ARP Endorsement.

On this page the brown fonts are quoted from Norcold letter to us & Norcold NHTSA letter.

The red fonts are quotes from Norcold patent application

13/279,361

menu item

Norcold ARP Endorsement.

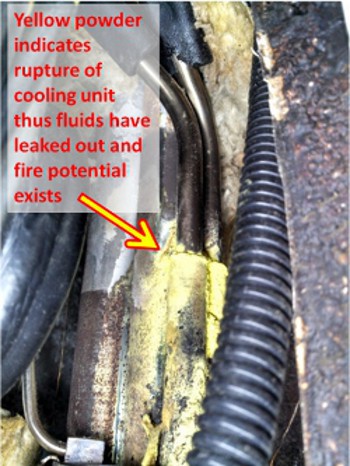

Seeing is believing! The old saying that a picture is worth 1000 words puts things into perspective.

Before moving on to the next section where we compare the Norcold Letter to Fridge Defend Facts,

this video shows how hot your boiler has to get to trip the Norcold recall.

Note: The Fridge Defend keeps the boiler temperature at less than half of the Norcold recall if installed and maintained

correctly!

Therefore, Fridge Defend is 2 times safer while avoiding costly fridge failure!!

What does the ARP Control do? When installed and maintained properly, the Fridge Defend by ARP Control helps prevent "catastrophic conditions" by not allowing the cooling unit boiler to experience "high temperatures" that permit the fluids in the system to overheat. These temperatures generally do not exceed 400F. If the fluids in the system are maintained at proper temperatures the result is limiting "stress, which in turn prevents personal and property damage" caused by a leak and the possibility of losses " due to fire and explosion when a system ruptures ".

"ARP Control solves problems with the refrigerator whereas the Norcold control solves a

legal issue.

If these fridges were in airplanes, the FAA would prohibit them to fly without the ARP Control

because the FAA mission is to

continually strive to improve the safety and efficiency".

Quoted from Retired Rolls Royce Avionics Engineer - Indio, CA 2013

Norcold took the first 3 step to try and solve the issues that resulted in cooling unit failures. Yes, there were 3 recalls to try and address this problem. We at Fridge Defend took the last step; we found the control parameter that protects the fluids within the cooling unit. Please click for ARPC LLC policies.

Read on to understand why you

may need a ton of cure if the Fridge Defend by ARP is not on

your fridge!

Please click here to see the science behind boiler temperature regulation.

This image is of a letter from Norcold which describes the Norcold 1200 series recall kit function. Click or tap the image to enlarge. Some potential customers and a few RV repair technicians have stated that there is not a difference between the Fridge Defend and the Norcold Recall, even worse, it is the party line to state that boiler protection such as the Fridge Defend is not necessary! This is just not true; the proof is in the correspondence.

Following we will use the right use of reason backed by science to help RV owners understand the difference between the ARP Control and factory recalls and repairs. We will include Norcold's correspondence so that the facts are gleaned clearly.

| Norcold Letter Quotes | Fridge Defend Facts |

| "Norcolds Recall Kit 634737 does not and cannot address off-level tilting conditions." | The Fridge Defend can and will address off-level tilting conditions. |

| "Norcold's Recall Kit 634737 functions only to address extremely limited, catastrophic conditions in which liquid is drained from the system (e.g. as a result of a leak)." | The liquid being drained from the system is the source of fires. The Fridge Defend address the most common root cause of the catastrophic conditions, that is the overheating of the boiler that leads to the destruction of the corrosion inhibitor. |

| "Heat input to the cooling unit is not adjusted until a sensed temperature of over 800°F." | Click here to see video of recall adjustment temperature , the Fridge Defend default1 setting adjusts heat input at ~422°F |

| "Such temperatures are only experienced at the location of the Norcold sensor if the cooling system experiences a leak." | Clearly one cause of an RV fridge failure is a leak. The effect of this type of failure is either the complete failure of your fridge, or possibly in the worst case fire and explosion when a system ruptures . Why go there? Would it not make more sense to address one of the known root causes of failure, such as the Fridge Defend by ARP already does? |

Clearly one cause of an RV fridge failure is a leak. The effect of this type of failure is either the complete failure of your fridge, or possibly in the worst case fire and explosion when a system ruptures . Why go there? Would it not make more sense to address one of the known root causes of failure, such as the Fridge Defend by ARP already does? This will all be explained in the next sections.

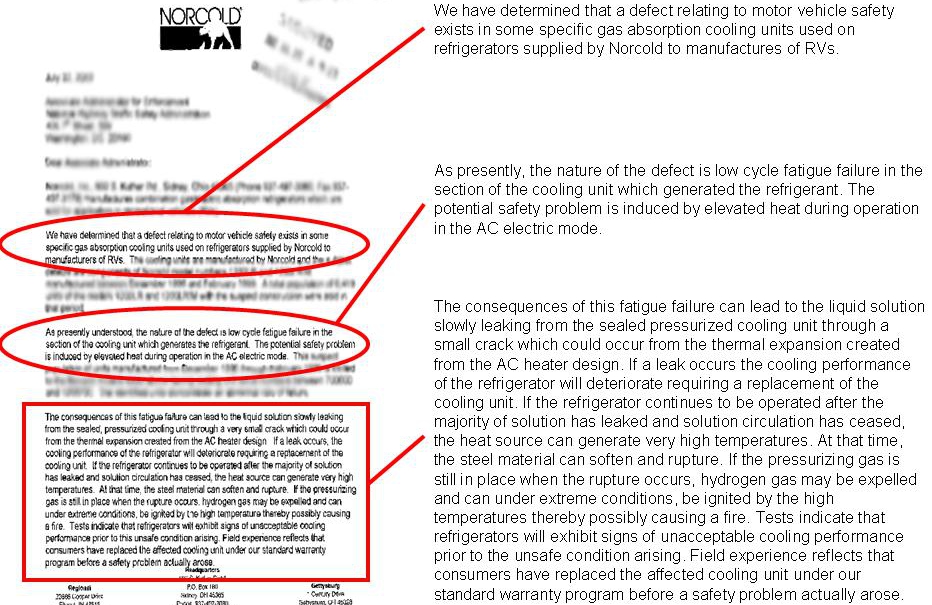

Following is the relevant contents of a letter from Norcold sent to the NHTSA in the year of 2002. Click or tap the image to enlarge. The table below has quotes on the left, and response to the quotes on the right. Let us know what you think?

Norcold Letter: We have determined that a defect relating to motor vehicle safety exists in some specific gas absorption cooling units used on refrigerators supplied by Norcold to manufactures of RVs.

| Norcold Letter to NHTSA | Fridge Defend Facts |

| "As presently understood, nature of the defect (and subsequent recall) is low cycle fatigue failure in the section of the cooling unit which generated the refrigerant (commonly called the boiler). | Clearly, at the time of the writing of this letter, an assumption was made, and in the course of time a program was implemented to resolve this described "boiler defect". 18 years later it is clear that the initial assumptions were only a small part of the big picture becaue failures & fires are still reported. |

| "The potential safety problem is induced by elevated heat during operation in the AC electric mode." | Norcold does acknowledge the need for the Fridge Defend by ARP in this statement. "Elevated heat" is a major contributing factor that leads to excessive stress on the cooling unit boiler assembly. The ARP control limits the temperatures in the boiler when installed and maintained correctly. |

| "The consequences of this fatigue failure can lead to the liquid solution slowly leaking from the sealed pressurized cooling unit through a small crack which could occur from the thermal expansion created from the AC heater design. If a leak occurs the cooling performance of the refrigerator will deteriorate requiring a replacement of the cooling unit." | Clearly, the Norcold engineers understand that "thermal expansion" results in leaks in the cooling unit. "Thermal expansion" is limited by limiting the temperature of the boiler assembly. |

| "If the refrigerator continues to be operated after the majority of solution has leaked and solution circulation has ceased, the heat source can generate very high temperatures." | And here we see the proof that the Fridge Defend by ARP is needed. Anytime the "solution circulation has ceased", the boiler (generator) can and will produce very high temperatures. This is the crux of the matter, the Fridge Defend by ARP is designed to limit boiler temperatures and in turn the "soften and rupture" that leads to failure. |

| "At that time, the steel material can soften and rupture." | Click here to see video of recall and steel material softening. Norcold's recall claims to turn off the heat at 800°F, the Fridge Defend default1 turns off heat at ~422°F. What does this mean? The steel in the boiler is almost twice as strong at 422°F than at 800°F. What do you want, safer or riskier? |

| "If the pressurizing gas is still in place when the rupture occurs, hydrogen gas may be expelled and can under extreme conditions, be ignited by the high temperatures thereby possibly causing a fire." | This is a well known fact now. It must be added that ammonia is flammable gas, so the hydrogen gas is not fully responsible. |

| "Tests indicate that refrigerators will exhibit signs of unacceptable cooling performance prior to the unsafe condition arising. Field experience reflects that consumers have replaced the affected cooling unit under our standard warranty program before a safety problem actually arose. | Clearly, operation of the cooling unit while the "solution circulation has ceased, the heat" does result in "very high temperatures" The Fridge Defend by ARP is proactive in prevention of operation of the cooling unit if the "solution circulation has ceased". The Fridge Defend is the best method to prevent unsafe conditions from arising in the first place. As a matter of fact, the essence of the Fridge Defend is to monitor the fluid flow at the boiler and turn off the heat source if the fluids stop flowing. Please click here to see video showing how this happens. Regarding the last sentence, "before a safety problem actually arose", hindsight brings this statement into question. |

NOTES:

1) We use the term "Default Fridge Defend Set-Point" simply because the Fridge Defend can be tuned for either a Dometic, Norcold, or Amish cooling unit fridge.

This will change the temperature that the Fridge Defend turns off a particular fridge heat source.